Introduction:

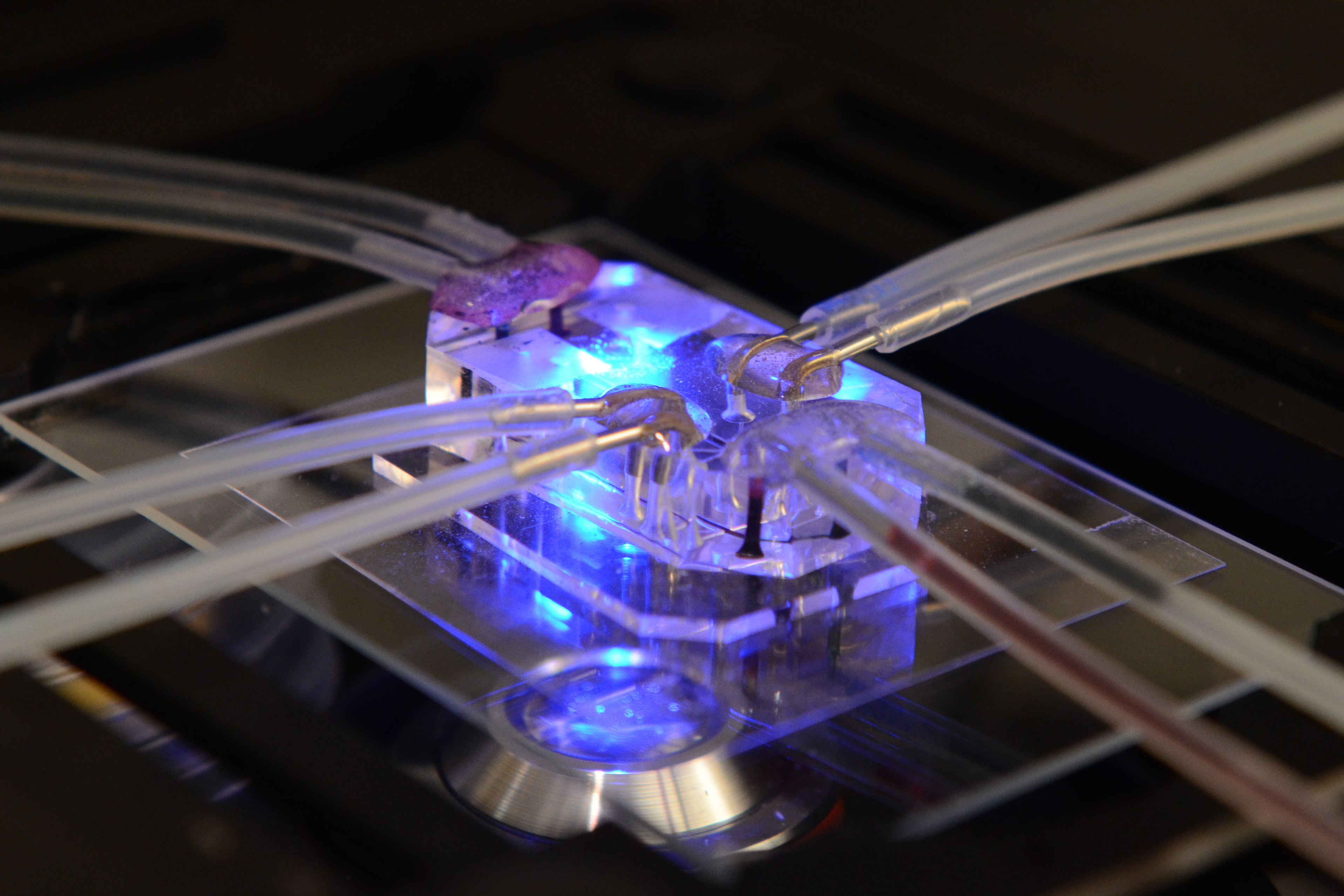

The organ-on-a-chip (OoC) technology represents a fascinating intersection of biology and microtechnology, allowing for the replication of crucial aspects of human physiology. These microfluidic devices consist of intricate networks of microchannels that manipulate minute volumes of solution. Within the chips, miniature tissues known as organs are cultivated to emulate specific tissue functions.

Advancements in Mimicking Human Physiology:

While simpler than native organs, OoCs have demonstrated their ability to effectively mimic human physiology and disease. These advanced in vitro systems enable researchers to study biological cells and tissues outside the body, recreating a biochemical and physical environment akin to in vivo conditions. OoCs occupy a unique position among model biological systems, offering greater control over the microenvironment and facilitating direct observation of cell and tissue behavior.

Expanding Applications and Recognition:

The development and utilization of OoCs have witnessed significant growth, with various iterations such as animal-on-a-chip, body-on-a-chip, and breathing lung-on-a-chip gaining attention. The World Economic Forum recognized OoCs as one of the top ten emerging technologies in 2016, indicating a pressing need for human-like testing systems in industries such as pharmaceuticals, cosmetics, food, and chemicals.

Advancements in Design and Fabrication:

OoC technology has benefited from advancements in tissue engineering and microfabrication, progressing from basic 2D cell cultures to complex 3D co-culture systems. Researchers now focus on optimizing cellular microenvironments, arranging cells geometrically to enable cell polarization, intercellular interaction, and signaling propagation. Additionally, the advent of induced pluripotent stem cell (iPSC) technology has opened avenues for personalized OoCs, utilizing patient-specific cells for studying disease phenotypes and drug responses.

Leveraging Microsystems Technology:

Microsystems technology, borrowed from the integrated circuit industry, has played a pivotal role in OoC advancements. This approach employs lithographic pattern transfer to fabricate nano- and micrometer-scale structures. It has enabled the development of microfluidic systems with integrated actuator and sensing capabilities, transforming the design, operation, and monitoring of in vitro bioreactors and cell biological systems.

Multi-Parametric Readouts and Integrated Biology:

Rather than traditional flat surfaces, OoCs now feature chips tailored to replicate the cellular and extracellular characteristics of specific organs, capable of responding to biochemical and physical cues to simulate organ function. Importantly, OoC systems facilitate multi-parametric readouts, offering insights into the integrated biology of humans and animals.

Guidelines for Developing OoC Experiments:

As OoC technologies continue to evolve, interest in the field is expected to grow. However, navigating the vast array of examples and applications can be daunting. To assist newcomers, this Primer provides an overview of key considerations when developing OoC experiments, summarizing important inventions and advancements. It covers principles for designing, fabricating, and operating OoCs, as well as techniques for extracting biological information through assays. The Primer also includes a discussion of diverse applications for OoC technology.

Creating In Vivo-Like Environments with OoCs:

OoCs are specifically designed to create an in vivo-like environment that guides cell assemblies into 3D tissues capable of replicating organ-level functions or to culture organotypic tissue while retaining functionality. This section presents an overview of the choices and considerations involved in designing OoCs for specific in vitro tissue experiments. The development of OoCs should be guided by their context of use, which relates to the intended application and the expected data. The review covers the necessary considerations, strategies, and equipment involved in setting up a new OoC experiment, and offers case studies showcasing the development of single-organ and multi-organ OoCs for drug research applications.

Challenges in Drug Development and the Need for OoCs:

Drug development is notoriously slow and expensive – it can take up to 10 years and cost more than $3 billion to bring a new compound from the lab bench to market. A major cause of this inefficiency is the traditional reliance on testing drugs in animals before they are tested in humans.

Organs-on-Chips as Human Biology Models:

A multidisciplinary team of Wyss Institute researchers and collaborators have adapted computer microchip manufacturing methods to create "Organs-on-Chips" (Organ Chips): microfluidic culture devices that recapitulate the complex structures and functions of living human organs.

Development and Validation of Organ Chips:

With additional grant support from the Defense Advanced Research Projects Agency (DARPA), Food and Drug Administration (FDA), and National Institutes of Health (NIH), Ingber and his team at the Wyss Institute developed more than fifteen different Organ Chip models, including chips that mimic the lung, intestine, kidney, and bone marrow.Lung On A Chip

Commercialization and Impact:

Just four years after the publication of their first paper describing living Organ Chips, a group of Wyss Institute researchers launched Emulate, Inc. in 2014 to further develop and commercialize Organ Chip technology, bringing these important research tools to market. Emulate's Organ-Chips have been installed in more than 150 labs including 17 of the top 25 global biopharmaceutical companies.

Conclusion:

The Wyss Institute is now using Emulate's Organ-Chips to conduct vital research on a wide range of human diseases and possible treatments for them, including COVID-19, influenza, malnutrition, radiation exposure, and cyst.

0 Comments